Introduction

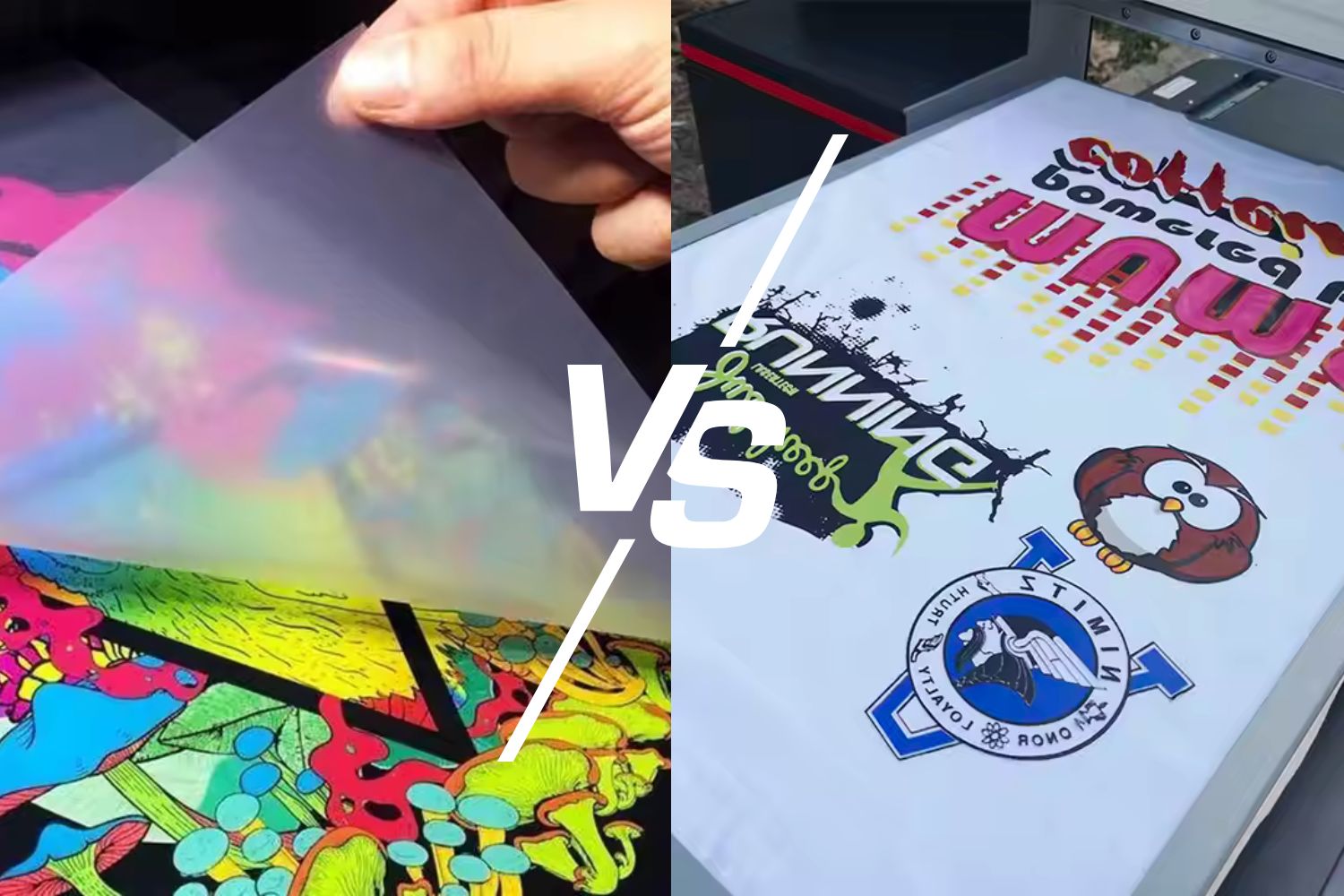

Do you run a textile workshop and want to offer the best printing solutions to your customers? You've probably heard of two techniques that are creating a stir: DTF (Direct to Film) and DTG (Direct to Garment). But between these two technologies, how can you make the right choice without making a mistake? Our DTF vs. DTG comparison will answer this question precisely.

Choosing the right technology is essential to ensure the quality of your textile prints while optimizing your profitability. The market is evolving rapidly, and with it, your customers' needs are becoming increasingly demanding. While DTG offers direct printing on natural textiles, primarily cotton, DTF offers remarkable flexibility, printing on cotton as well as polyester or nylon.

In this DTF vs. DTG comparison , we'll analyze these two techniques from different perspectives: production costs, textile versatility, maintenance, and print quality. You'll discover how these aspects concretely influence your workshop's performance. This way, you can make an informed decision that perfectly matches your business needs.

For example, imagine a workshop specializing in custom polyester sportswear: opting for DTF after studying a DTF vs. DTG comparison would allow it to better satisfy its customers and avoid costly mistakes. Conversely, a company focused on complex cotton designs will certainly find happiness with DTG after consulting this same comparison.

In this article, we'll answer all your questions. Stay tuned to discover which technique is best for your business. And don't forget: to get the most out of these technologies, equip yourself with the best DTF & DTG inks available on our website!

Production costs: DTF or DTG, which technique is more profitable?

Initial costs

In this DTF vs DTG comparison , you should consider the initial setup costs. DTG generally requires a higher initial investment due to the specific machinery, unlike DTF, which can use repurposed printers. For example, a professional DTG printer will easily cost between €10,000 and €25,000, while DTF setup can be completed from as little as €3,000 to €5,000.

Discover our economical and high-quality range of DTF Inks & DTG Inks to further reduce your costs!

Cost of consumables

The cost of inks and films is also a determining factor in your choice between DTF and DTG. For example, white DTG ink is often very expensive (between €150 and €200 excluding VAT per liter for competitors). Conversely, our white DTF inks are available from €90 excluding VAT, allowing for substantial savings on your margins in the long term.

Optimize your profitability with our selection of DTF Inks & DTG Ink

Cost of maintenance

Maintaining DTG machines can generate significant additional costs, particularly due to frequent printhead clogging. DTF, thanks to its specific formulation, reduces this risk of clogging and therefore maintenance costs.

Ensure peace of mind with our complete collection of DTF Inks & DTG Ink

Versatility: Which method should you choose depending on your textile supports?

Printing on natural textiles

DTG is ideal for cotton and natural textiles thanks to its direct printing. This DTF vs. DTG comparison confirms that if you work primarily on cotton t-shirts or sweatshirts, DTG can be a good choice.

Order your DTG ink suitable for all types of media.

Printing on synthetic textiles

DTF excels on synthetic materials like polyester, unlike DTG. For example, DTF is clearly more suitable for printing on sportswear.

Discover all our options for synthetic textiles with our DTF collection

Printing on various textiles

If your shop handles both natural and synthetic textiles, our DTF vs. DTG comparison leans heavily toward DTF for its great versatility and ease of use on all textiles.

Don't limit yourself any longer, try our range of DTF Inks and Supplies.

Maintenance: Ease of use and durability of equipment

Daily maintenance of equipment

In this DTF vs DTG Comparison , you will find that the DTF requires less daily maintenance, significantly reducing your time spent on maintenance.

Simplify your daily routine with our DTF Inks and supplies.

Printhead durability

DTG can often experience printhead clogging issues, resulting in frequent replacements. Thanks to DTF's anti-clog formula, you'll change your heads three times less often!

Extend the life of your equipment with our DTF inks and supplies.

Managing printing errors

DTF offers the advantage of easily correcting small errors without losing your textile, thanks to specific products such as Flex Remover.

Quality and final rendering: What result for your prints?

Visual color quality

DTG is known for its precise details on natural fabrics. However, DTF also offers excellent color quality, regardless of the substrate.

Strength and durability

DTF has an undeniable advantage: its exceptional resistance to washing and wear, perfect for sports or professional textiles subjected to harsh conditions.

Flexibility and touch

Contrary to popular belief, DTF offers a soft, fine, and flexible feel, comparable to DTG. Your customers will appreciate this comfort every day.

Offer the best to your customers with our DTF inks and supplies.

Conclusion

After reading this DTF vs. DTG comparison , you now have all the keys to choosing the printing technology that's perfectly suited to your business. Whether it's production costs, versatility, maintenance, or final quality, the choice between DTF and DTG depends above all on your specific needs.

For example, if you place a lot of orders on synthetic textiles, DTF will clearly be the ideal solution. If, on the other hand, you prefer cotton, DTG can also be a good option.

Don't waste time: equip yourself with the best today DTF Inks & DTG Inks for successful and sustainable production.

In summary, this DTF vs DTG Comparison was designed to facilitate your decision and clearly guide your strategic choices for an efficient and profitable textile workshop!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.